POWERBLOCS - PINS INSTEAD OF FINS

NEW TO OUR PORTFOLIO: 48 STANDARD PIN HEAT SINKS!

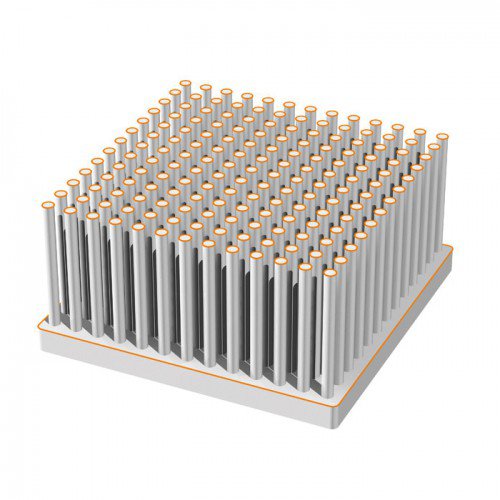

Powerblocs or pin heat sinks are generally known for their thermal management of processors, ICs, BGA components, LEDs or similar applications.

Aluminum’s best possible thermal conductivity of >220 W/mK is achieved through a nearly pure aluminum alloy (AL99,5) and a high material density through impact extrusion. It has an ideal material structure whereby the impact extrusion forces the material to flow from the base to the pin tips. This is identical to the way the heat will flow later through the heat sink.

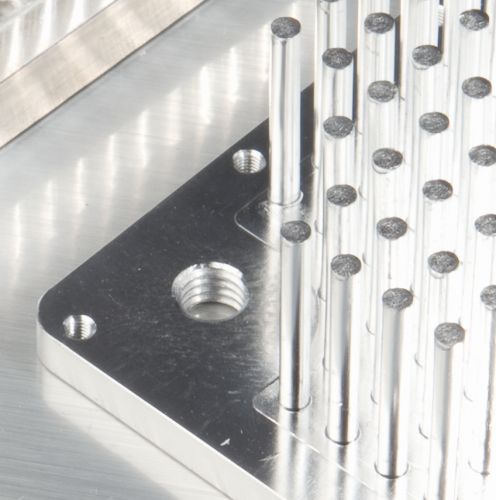

Alutronic now have improved tooling technology for impact extrusion which makes it possible to achieve Powerblocs in dimensions up to 240mm x 160mm x 40mm with a high density of pins.

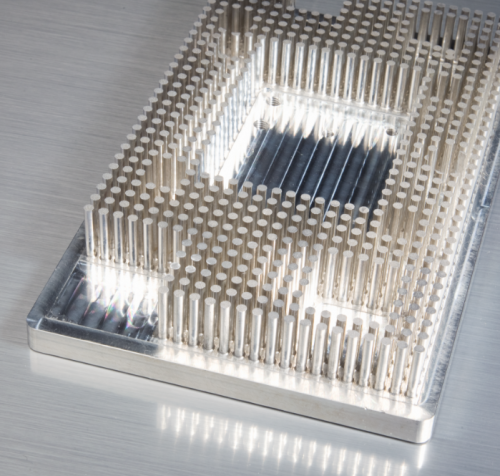

An example can be seen in Alutronic’s Powerbloc PB200-120-40-1:

With 1215 pins, a diameter of 3.2mm and a height of 30mm which can fit in an area of 200mm x 120mm, this equates to 9 pins on an area of 12mm x 12mm. In this case, the shortest distance between the fins is 1.2mm.

This high density of pins allows for an extremely large surface area for energy transfer to the air. This results in an extremely strong thermal performance of the Powerbloc, given its compact size.

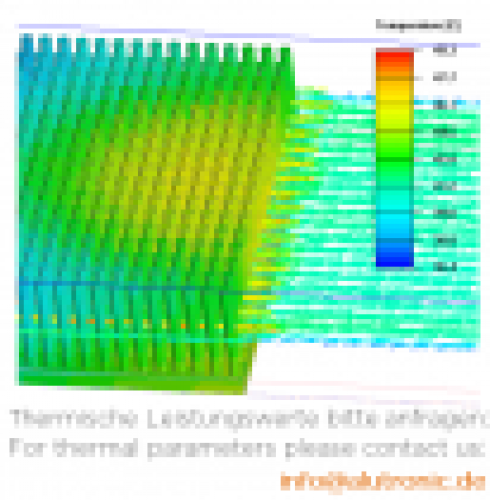

With a temperature gap of 55K (T component - T ambient = 80°C – 25°C = 55K) the Powerbloc PB200-120-40-1 can dissipate the following according to our simulation:

- 60W of thermal energy, or 0.91 K/W with natural convection

- 360W of thermal energy, or 0.17 K/W with forced convection. Airflow is vertical (fan on top of heat sink) and velocity is 2 m/s

- 550W of thermal energy, or 0.1 K/W with forced convection. Airflow is horizontal (channeled through the heat sinks from the side)

With this thermal capacity, Alutronic Powerblocs will perform in your applications of IGBTs, amplifiers, MOSFETs, LED and similar electronics.

Alutronic Powerblocs utilizing forced convection should be used within your component cooling design. Our research has found that vertical forced convection (fan-on-top) improves the thermal performance five to nine times compared to leaving the Powerbloc to natural convection. If you are able to design a channel for the airflow and have the air flow horizontal through the fins, you will improve the thermal performance of the Powerbloc by another 20-40% compared to the fan-on-top solution.

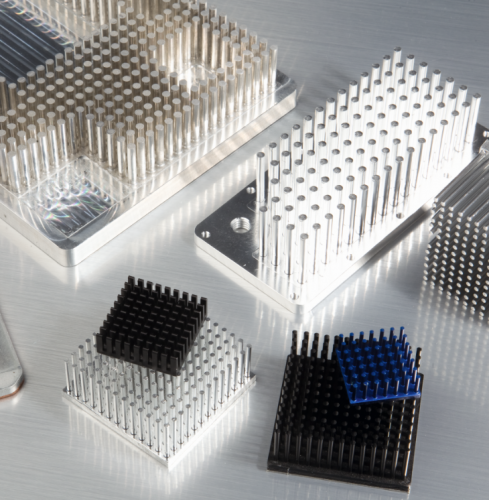

For cooling down LED modules without use of a fan, Alutronic offers round-cut Powerblocs up to 50mm diameter in size.

For our complete overview of Powerbloc standards, please review the catalogue below as a PDF download.

In addition, Alutronic provides:

- Powerblocs in customized shapes

- Surface treatment

- Milling & drilling

- Pre-application of heat-conductive, adhesive foil

- The fitting fan, apart or pre-mounted

Alutronic offers detailed analysis of the thermal performance of each shape, whether it be for natural convection, top-down or horizontal forced airflow. If you are interested in the thermal performance of a specific Powerbloc, just send a short request to info@alutronic.de.

POWERBLOCS - Pins Instead of Fins