ALUMINIUM surface Finishing

Your partner in anodising - with over 30 years of experience in electroplating, we are your partner for anodised coatings..

Contact usANODISING SPEcIALIST Since 1989

For anodising, you and we have special demands on occupational safety, environmental protection and quality. We meet these demands with our highly trained team and state-of-the-art technology.

Your partner for anodising refinement

With our experience and the completely renewed anodising line at the Halver site, we would like to achieve excellent results for you by surface finishing.

Your contact

Jan Holve

Leitung Eloxalwerk

Tel.: +49 2353 / 915 392

eMail: holve@alutronic.de

Whether single part anodising, small or large series, in our anodising plant Mr Thomas Lauff has perfectly coordinated several processes to guarantee efficient operation for our customers.

We look forward to answer your questions and to implement your project. Feel free to contact us!

Contactform

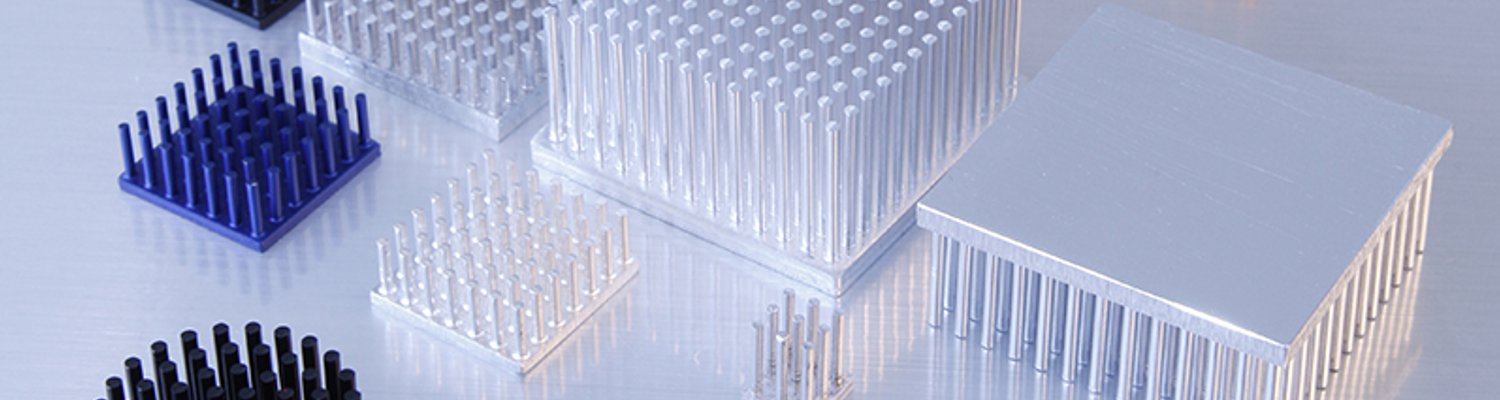

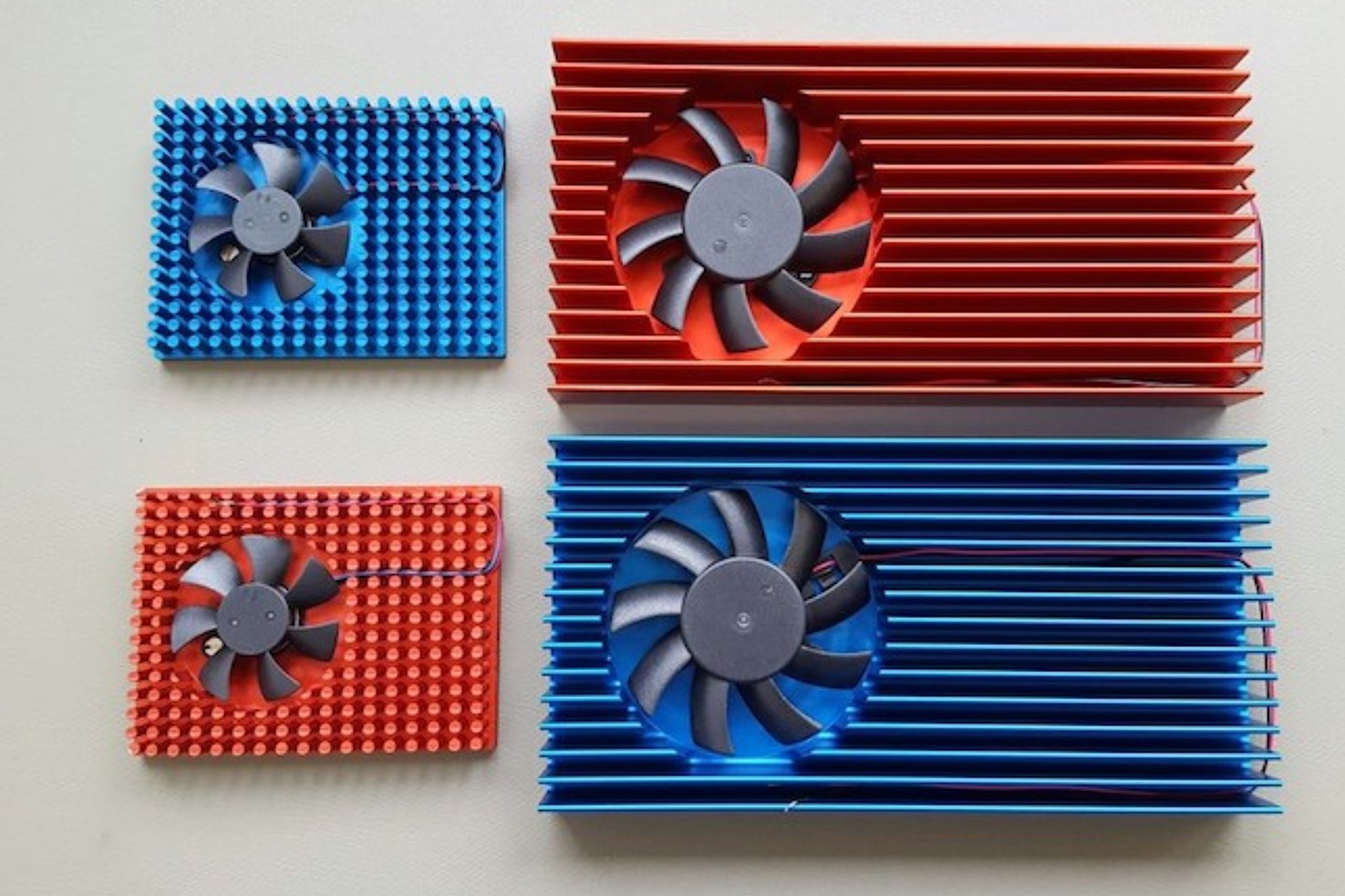

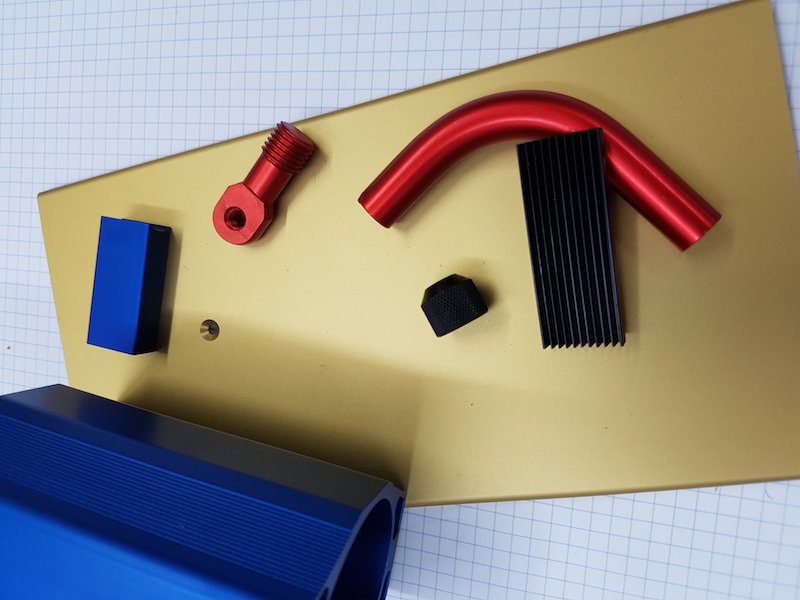

Anodising: Protection + Finishing

An anodised coating offers for your components surface protection, electrical insulation and decorative solutions. With a black anodised coating, additional improved heat radiation is achieved.

Test us!

Aluminium surface finishing

Where the natural quality of the aluminium material is not sufficient, the aluminium surface is refined by an anodised layer. This layer can be up to 30µm thick. This surface treatment determines the final appearance of the product.

Applications for anodised aluminium are among others the electrical industry, the construction industry, the automotive industry and the food industry.

At Alutronic, anodic oxidation (anodising) is carried out using a direct current sulphuric acid process. In this process, the purity and condition of the aluminium is a decisive factor.

In the manufacturing process, electricity, H2O and H2SO4 transform the aluminium surface into aluminium oxide. This so-called anodised layer lies two parts in and one part on the workpiece.

Corrosion resistance

Better heat radiation

Surface hardness

Anodising & Advantages

Aluminium in its raw state reacts in the air and forms an uncontrollable, often unintended unsightly oxide layer due to the reaction with oxygen or weather-related influences. Anodising is a possibility for the controlled creation of a protective layer. In this process, the top layer of the part to be anodised is transformed and an oxide is formed. It protects your aluminium part from corrosion as long as there is no surface damage from scratches or similar on the surface.

What is anodising?

Anodising - also known as "anodising" or "anodising process" - is an electrochemical process. In the field of surface technology, the process is used to create a thick, protective and extremely hard layer over an aluminium workpiece in a controlled manner by means of anodic oxidation. In this process, the top layer of the workpiece is converted into an oxide or hydroxide. Depending on the desired application, it can reach a thickness of between 5 and 30 µm.

IN PRODUCTION

Regular control oft he chemistry

Fully automatic SPS system

Anodise supports are fitted

Aluminium surface finishing

Where the natural quality of the aluminium material is not sufficient, the aluminium surface is refined by an anodised layer.

Advantages of surface treatment

This layer can be up to 30µm thick. This surface treatment determines the final appearance of the product.

- Free of corrision

- Hardness of surface

- Better heat radiation

- Weather resistance

Manufactoring process

In the manufacturing process, electricity, H2O and H2SO4 transform the aluminium surface into aluminium oxide. This so-called anodised layer lies two parts in and one part on the workpiece.

Areas of application

Applications for anodised aluminium includeamong others the electrical industry, the construction industry, the automotive industry and the food industry. At Alutronic, anodic oxidation (anodising) is carried out using a direct current sulphuric acid process. In this process, the purity and quality of the aluminium is a decisive factor.

Anodised layer

This anodised layer is electrically non-conductive and has a high breakdown resistance. The workpiece is contacted in supports (frames) made of titanium or aluminium to ensure a safe current flow. The layers, which are colourless in themselves, can be coloured in different shades by incorporating colour pigments.