COPPER + ALUMINUM TEAM UP!

Heat Dissipation Increased 30% to 50%!

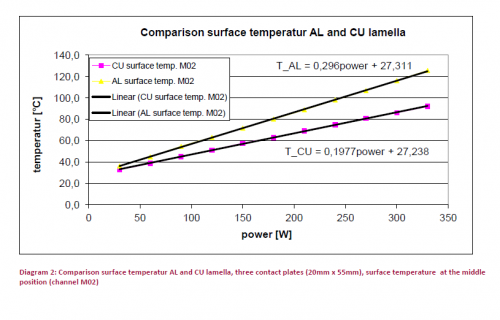

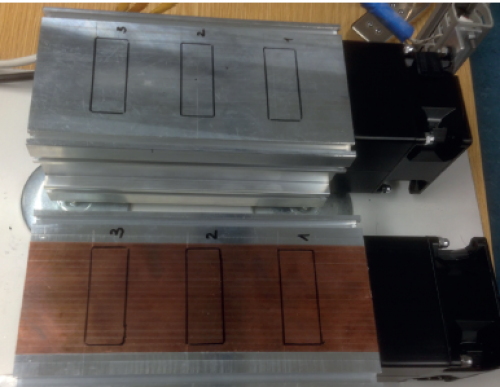

Alutronic presents the new LKC series. Based on the popular LK series (press-joined Lamellas from AlMgSi 0,5 F 22) LKCs feature a material combination of aluminum for mechanical purposes (Side panel for fixation) and copper for the thermal purposes (base, mounting surface, lamella). For example: The thermal performance of the LKC10/200/A compared to the LK10/200/A is 30% better in terms of thermal resistance (RthK 0,08 K/W) and up to 50% better in terms of maximum capacity for heat dissipation (Pv 300W) .

LKC10/200/A was technically compared to the LK10/200/A by laboratory analysis. The results of this comparison are available for download (check below).

The LKC10/200/A is now available on stock. Go directly to the product page:

Copper and aluminum are joined in a patent pressing process. This process allows a high level of freedom in terms of design. Cooling units can be easily customized. Designers are free to change the thickness of the lamella, distance between lamellas, base height, total width and total length as well as mixed patterns of copper and aluminum.

For all cases where high power losses meet limited design space the Alutronic combinations of copper and aluminum provide the ideal solution!

Technical Comparison LKC10/200/A vs. LK10/200/A

Technical Comparison LKC10/200/A vs. LK10/200/A